Imagine a house being “drawn” into existence, layer by layer — as if a giant robotic cake-decorator were piping not frosting, but concrete walls. That’s 3D concrete printing in simple terms. And in India, this technology has transitioned from experimental curiosity to practical implementation at remarkable speed. It positioned 3D-printing as a strategic tool for PMAY’s mission of creating safe, affordable and disaster-resilient housing for every rural family.

In a nation grappling with land scarcity, rising material costs, a growing housing demand and the urgent need for sustainable construction practices, 3D-printed homes are no longer a fringe innovation — they are a viable, scalable solution. This blog dives deep into the journey: the science behind the tech, the key pilot projects, the economics, environmental impact, social implications, real-world challenges, and the roadmap for mainstream adoption. The future of Indian housing might not be built brick by brick — but printed, layer by layer.

Pioneering Sustainable Construction: Godrej Properties Launches India’s First 3D-Printed Villa in Pune

Early Beginnings & First Experiments

Genesis of 3D Concrete Printing in India (pre-2020)

Long before headlines, 3D concrete printing — a technique widely tested globally — quietly reached India’s research labs and startups. Engineers and architects began experimenting with digital designs, robotic extrusion and specialized concrete mixes. The idea was simple: could automation and layering replace labour-intensive brick-and-mortar? The promise of speed, waste reduction and custom shapes sparked early interest.

First Practical Success: Tvasta Manufacturing Solutions & IIT Madras (2020–2021)

In 2021, researchers and alumni at IIT Madras, via startup Tvasta, turned theory into reality. They printed what is credited as India’s first 3D-printed house on campus.

- This was a single-storey home, roughly 600 sq ft.

- The entire structure was printed using a specialized concrete mix and automated extrusion, reportedly in just a few days — a stark contrast to the 4–5 months typical for conventional housing.

- The inauguration took place on April 27, 2021, marked by the presence of then Union Finance Minister.

Why it mattered

- It proved that 3D printing can handle climate, concrete mix, and structural needs in Indian context.

- It offered a glimpse of cheaper, faster housing — especially valuable for affordable housing and slum-rehabilitation projects.

- It put India on the global map of countries experimenting with 3D-printed housing, sending a signal to builders, regulators and policymakers that it was more than a fad.

From Houses to Public Infrastructure: The 2023 Leap

Larsen & Toubro (L&T) Builds India’s First 3D-Printed Post Office, Bengaluru (2023)

The next big leap came in 2023 — when 3D printing crossed from prototype housing to public infrastructure. In March 2023, L&T, with technical support from IIT Madras, began constructing a post office building in Cambridge Layout, Bengaluru, using 3D concrete printing.

- The building covered a built-up area of 1,021 sq ft (approx. 95 m²).

- The construction reportedly completed in 43 days — much faster than the roughly 8 months conventional method would take for a similar structure.

- According to L&T, the cost was about 40% lower than conventional construction would have been.

- The post office was inaugurated on 18 August 2023 by the Union Minister for Railways and Communications, Ashwini Vaishnaw, and received public praise, including from the Prime Minister.

This project marked a turning point: 3D printing was no longer an academic experiment or niche housing test — it was being used for real public-facing infrastructure.

What this signaled

- Validation of 3D printing for public infrastructure by large contractors — not just startups.

- Demonstration that even government-run services can adopt advanced construction technology, which helps legitimize the tech across sectors.

- A stronger case for scalability — if a public building works, why not dozens of homes, schools, community centers, disaster shelters, etc.?

How 3D house printing is being adopted under PMAY (Pradhan Mantri Awaas Yojana) and Private Players

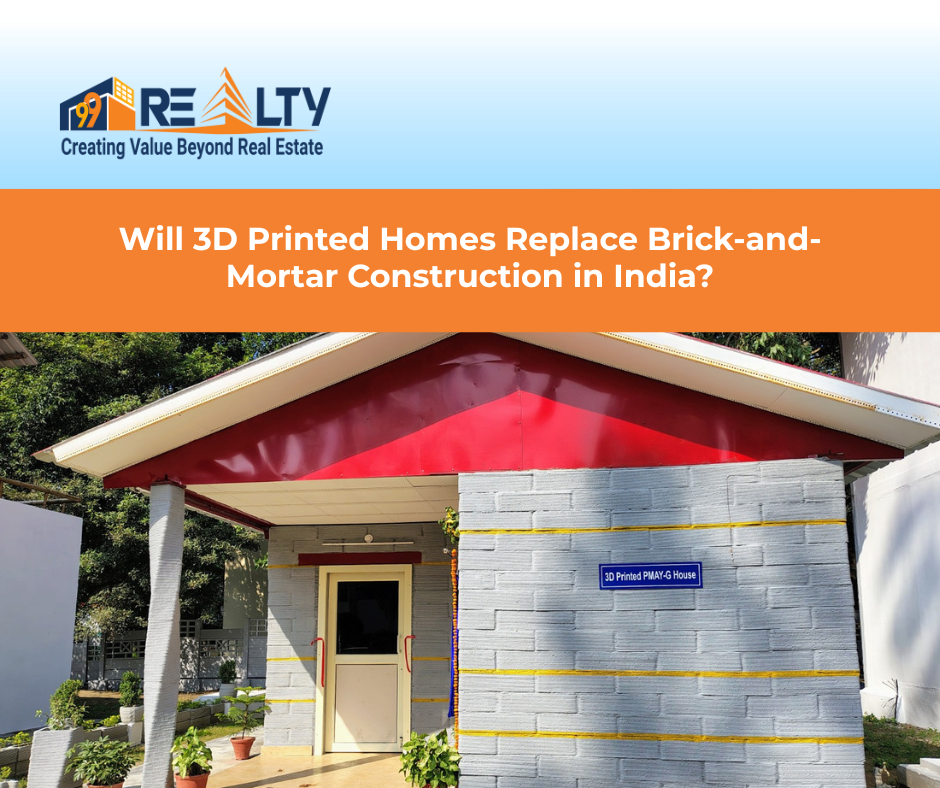

On 1 October 2025, India achieved a milestone in rural housing: Pradhan Mantri Awaas Yojana‑Gramin (PMAY-G) saw the unveiling of the country’s first 3D concrete-printed rural house — built at CSIR‑CBRI, Roorkee. The inauguration, led by Dr. Chandra Sekhar Pemmasani, underscored the government’s ambition to combine innovation with affordability and sustainability in rural homes. The printed home promises a faster, cost-efficient alternative to traditional housing — potentially transforming how rural shelters are built across India under PMAY’s vision. — speed of construction, control over unit costs, and reduction of construction waste.

Godrej Construction is a key private player in India’s 3D construction sector, largely due to its partnership with the IIT-Madras startup and Tvasta Manufacturing Solutions. This collaboration focuses on deploying 3D construction printing (3DCP) technology for projects such as housing, infrastructure, and disaster relief, and it has already achieved milestones like the completion of India’s first 3D-printed villa and a functional office building.

How 3D Concrete Printing Works: The Technology Behind the Headlines

The Process: From CAD to Concrete Layers

At the heart is simple automation: a 3D model (CAD) is fed into the printer, which lays down a special concrete mix, layer by layer, like a giant icing nozzle building a cake — but vertical walls instead of frosting.

Printers may use gantry systems or robotic arms; the latter offer flexibility in design, but both aim to reduce manual formwork, shuttering, and scaffolding.

Materials & Concrete Mixes: Key to Indian Success

Standard concrete doesn’t cut it: the mix must harden fast enough to support subsequent layers, yet stay extrudable. Additives such as accelerators, plasticizers and fibres — and sometimes recycled aggregates — are used to adapt to India’s climate and resource constraints. Tvasta claims their mixes help reduce waste and carbon footprint, making construction more sustainable.

Why India Is a Fertile Ground for 3D-Printed Construction

Urgent Housing Demand + Affordability Pressure

With millions still needing affordable housing — and conventional construction often slow or expensive — 3D printing offers a pathway to deliver standardized, low-cost homes quickly. The speed of printing (days instead of months) can accelerate housing-for-all objectives.

Labour Constraints & Safety Gains

Traditional construction in India is labour-heavy, often unregulated, and safety is a concern. 3D printing reduces dependence on manual labour, shifting towards skilled machine operation and finishing work — which can improve safety standards and reduce on-site accidents.

Design Flexibility & Customization for Diverse Needs

Indian architecture is diverse: regional design preferences, curved roofs, verandahs, optimization for climate. 3D printing excels at customized geometry — curved walls, integrated conduits, modular layouts — making it easier to build houses suited to local tastes, not cookie-cutter models.

Reduced Waste and Potential for Sustainable Materials

Traditional construction wastes formwork timber, excess concrete, leftover bricks. 3D printing cuts formwork entirely and uses concrete precisely, reducing waste. If mixes incorporate recycled aggregates or industrial byproducts, the embodied carbon and environmental footprint can shrink further. Early projects — like that by Tvasta — emphasise this eco-friendly potential.

Challenges, Dilemmas & Hurdles (Why the Road Ahead Isn’t Smooth)

Regulatory and Code-Approval Gaps

Most Indian building codes and municipal regulations are written with brick-and-mortar or RCC frame + masonry in mind. Printed load-bearing walls, layer-bonds, seismic detailing, MEP (plumbing/electrical) conduits — these aren’t yet codified. Until regulators update codes and formally recognize 3D-printed structures, large-scale adoption will remain risky.

Long-Term Durability and Climate Performance: Uncertain Terrain

While prototypes have been built, long-term data is scarce. Questions remain: how will printed walls fare in strong monsoon-induced dampness, coastal salinity, heat cycles, earthquakes? Can printed structures be retrofitted or repaired easily if cracks develop? The lack of decades-long records makes lenders, insurers and buyers cautious.

Skilled Workforce, Supply Chains & Maintenance

3D printing reduces labour, but increases demand for skilled operators, technicians, and maintenance staff. Also, printers, spare parts, specialized concrete materials need supply chains. In remote or rural areas, setting up such back-end infrastructure is a challenge. Maintenance, repairs and retrofitting over decades may require special training and materials — a hurdle in widespread rural deployment.

Cost & CapEx for Printers: Who Pays Up-front?

While a printed house/post office saves cost overall, the printer hardware itself is capital intensive. For individual homeowners or small contractors, high upfront investment may deter adoption. Only large contractors or government-backed projects seem currently capable of bearing that cost.

Social & Cultural Resistance: “Will it feel like a real home?”

In many parts of India, masonry houses have cultural, emotional significance. For society to accept printed walls as “real homes,” there needs to be assurance on safety, comfort, aesthetics, and long-term performance. Lack of familiarity may spark resistance or distrust among potential buyers.

Where 3D-Printed Construction Makes Most Sense in India (Even Today)

Affordable Housing & Government-Backed Mass Housing Schemes

Government schemes aiming to deliver large numbers of houses (in urban or semi-urban areas) can leverage 3D printing to reduce cost and time. A standardised design, printed repeatedly with minimal labour, could drastically lower per-unit cost and accelerate delivery — perfect for slum rehabilitation or rapid housing rollout.

Public Infrastructure & Community Buildings

As shown by the Bengaluru post-office project: public buildings, community centers, sanitation blocks, bus-shelters or even rural clinics can adopt 3D printing. For such uses, benefits like speed, lower maintenance, and design flexibility matter more than premium finishes.

Disaster Relief & Remote/ Rural Housing

In disaster-hit zones or remote rural locations where skilled labour and materials are scarce, transport logistics are complex — mobile 3D printers (or modular printed units) can offer rapid, low-cost, on-site housing or shelters. The lower dependency on bricks, cement supply chains and manual labour makes this especially suited for crisis response.

What Needs to Happen Now — Roadmap for India to Embrace 3D Printing at Scale

Update Building Codes, Standards & Testing Frameworks

Regulatory bodies, in coordination with industry and academia, must create codes that define structural requirements, seismic safety, waterproofing/damp-proofing, MEP integration for 3D-printed houses. They must also establish independent testing and certification labs so printed buildings can be certified for safety, durability, and insurance eligibility.

Build Ecosystem: Printers, Materials, Maintenance & Skilled Workforce

Encourage manufacturing of 3D printers domestically, concrete-mix producers to develop local low-carbon mixes, training institutes to produce skilled operators, and maintenance/repair networks for long-term upkeep. Without this ecosystem, adoption will remain limited to pilot projects.

Financing & Incentives: Lower Upfront Costs, Encourage Adoption

Government subsidies for printers, tax benefits for low-carbon concrete, or soft loans tied to affordable housing — all could lower the financial barrier. Public–private partnerships, collaborations with non-profits (like those done by Tvasta + Habitat for Humanity) can also help.

Demonstration Projects & Community Awareness

More pilot homes, houses for low-income groups, community buildings — visible, functional structures — will help build public trust. Outreach, awareness campaigns about durability, cost, environmental benefits, and maintenance will address social and cultural hesitation.

The Future Outlook: Potential Scenarios for 2025–2035

- Gradual scaling in urban affordable housing: Once codes and supply chains are ready, 3D-printed homes may gradually appear under housing-for-all or slum-rehabilitation programmes.

- Hybrid construction models: Some houses may combine 3D-printed walls with traditional masonry or RCC frames depending on needs (e.g., multi-storey, earthquake prone zones).

- Rural and disaster-relief adoption: Mobile printing units could emerge as part of disaster-management plans or rural housing drives.

- Green/conservation-oriented construction: With optimized designs and sustainable mixes (recycled aggregates, fly-ash, geopolymer cement), 3D printing could reduce waste, embodied carbon and environmental footprint.

- New business models & economies of scale: Printer-as-a-service firms, modular-home manufacturers, materials suppliers, maintenance services — all creating ecosystem jobs beyond traditional masonry.

However, this future isn’t guaranteed. It depends on policy clarity, reliable material supply, accepted standards, public acceptance, and long-term performance proving out.

Conclusion: A Cautiously Optimistic Road Ahead

India’s journey with 3D-printed houses — from a demonstration home in 2021 to a public post office in 2023 — shows a technology ready for next-stage scale. The promise is irresistible: homes faster, cheaper, greener; infrastructure that can adapt; roofs over many more heads. But there are real dilemmas: regulatory gaps, long-term durability concerns, financing PRINT hardware costs, and cultural acceptance.

If stakeholders — government, academia, industry and communities — move deliberately to address those challenges, 3D printing can genuinely transform how India builds. The next 5–10 years could see 3D-printed houses shift from novelty to everyday reality. But it will take collaboration, standards, transparency and trust.

Need Help?

Need help evaluating a property or planning your next move in the market?

Reach out to 99 REALTY – your trusted real estate partner for smarter choices.

Subscribe to get updates on our latest posts and market trends.

Join The Discussion